Silk threads go through a carefully considered creation process, using natural sources of silkworms, usually mulberry silkworms (Bombyx mori).

- It begins with the collection of silkworm cocoons, each of which unfolds to create a span that can reach a length of up to 1,500 meters.

- The collected cocoons are then boiled or steamed to soften the sericin, the protein that binds silk fibers together. This softening process makes it easier for the silk threads to unwind.

- Once softened, the cocoons are unwound, often using a device called a “winding machine”. As the cocoons unravel, long silk fibers are wound onto spools.

- The unwound silk fibers are then twisted, creating threads that are extremely durable.

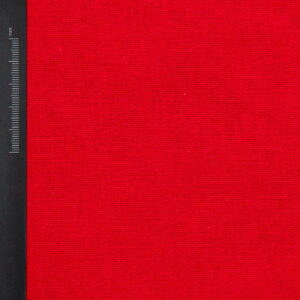

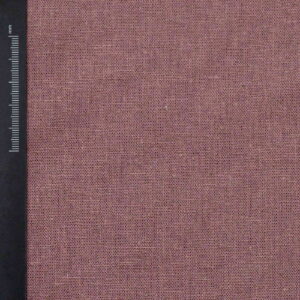

- The created threads readily absorb dyes, and the silk absorbs dyes perfectly and is resistant to fading.

- The finished silk threads are wound onto bobbins, cones or skeins, ready for distribution and versatile in textile and sewing applications.

The “26/6” designation in the threads refers to their thickness. What does this mean exactly?

The first number (26 in this case) indicates the thickness of the thread. This number indicates the number of meters per gram of yarn. The higher it is, the thinner the thread is. In this case, it is a thick thread – perfect for sewing, embroidery and even lace-making.

The second number indicates the number of strands twisted together to form a thread. In this case, the “6” means that six individual strands have been twisted together to form the final strand.

So “26/6” means a thick silk thread composed of two single threads, each gram of which is 26 meters of thread.

Silk is one of the oldest known textile materials, dating back thousands of years. Despite their delicate appearance, silk threads are extremely durable, and the key to this resistance lies in the chemical composition of silk, mainly in proteins, especially sericin and fibroin.

- Fibroin gives silk threads exceptional strength.

- It has the ability to absorb significant amounts of water, which makes the threads flexible and rot-resistant.

- Silk fibers are also resistant to UV radiation, which means that their strength remains intact even in intense sunlight.

This unique combination of features contributes to the preservation of the color of dyed silk threads, making silk an ideal material not only for the production of clothing, but also for various applications, such as sewing bedding or interior furnishings.

Silk threads, known for their lightness and softness to the touch, have gained popularity in the fashion industry. The extraordinary durability of silk allows for long-term use while maintaining its original and elegant appearance for years.

The history of silk in Europe is a fascinating journey that began in ancient China and continued for centuries before gaining recognition in European circles.

Silk was one of the oldest and most valued textile materials in China, where the secret of its production was carefully guarded for over 2,000 years.

China maintained a monopoly on silk, exporting it to Europe via the Silk Road. Revealing this beautiful material had serious consequences, including the possibility of death. In 550, two monks undertook a risky mission and transported this closely guarded knowledge to Byzantium. Justinian I, the ruler of Byzantium, desired Chinese silk for its exceptional quality and lucrative profits. Legend has it that the monks hid silkworm eggs in bamboo sticks, cleverly disguised as ordinary walking sticks. However, historical accounts challenge this narrative.

Some sources suggest that Byzantium may have been involved in the breeding of silkworms earlier, and the existence of silk production in Syria in the 5th century AD and even in the 4th century BC. in Greece, undermines the classical story of monks and their mysterious transport.

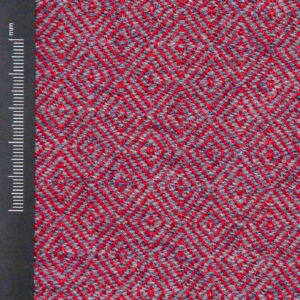

Despite doubts about the method of transportation, Byzantine silk production expanded rapidly. The secrets of production reached wide circles, and textiles were decorated with intricate patterns, from religious scenes to fantastic creatures. The imperial court actively supported the industry by commissioning exclusive designs, which contributed to the creation of unique silk fabrics.

Byzantine silks gained enormous popularity in early medieval Europe, although they were valued not only for their beauty, but also for their high price. Only the wealthiest could afford to own these luxurious fabrics.

In this way, silk in Europe not only survived the long journey, but also became a symbol of luxury and elegance, winning the hearts of elites and consumers on the continent.