Silk threads undergo a meticulous creation process utilizing natural sources from silkworms, typically the mulberry silkworms (Bombyx mori).

Initiating with the gathering of silkworm cocoons, each cocoon unfurls into a spread that can reach up to 1,500 meters in length. Subsequently, the collected cocoons undergo boiling or steaming to soften the sericin, a protein binding the silk fibers together. This softening facilitates the unwinding of the silk threads.

Once softened, the cocoons are unwound, often employing a device known as a “reeling machine.” As the cocoons unravel, the extensive silk filaments are wound onto spools. The unwound silk fibers then undergo twisting to create threads of remarkable durability.

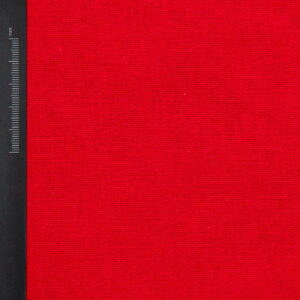

The resulting threads readily accept dye, with silk exhibiting excellent dye absorption and resistance to fading. The finalized silk threads are wound onto bobbins, cones, or skeins, prepared for distribution, and versatile for use in various textile and sewing applications.

The “20/2” marking in the threads refers to their thickness. What exactly does it mean?

The first number (20 in this case) indicates the thickness of the thread. This number indicates the number of meters per gram of yarn. The higher it is, the thinner the thread is. In this case, it means a medium-thick thread – perfect for sewing, embroidery and even lace-making.

The second number indicates the number of strands twisted together to form the thread. In this case, “2” means that two single strands are twisted together to form the final strand.

So “20/2” means a thick silk thread made of two single threads, each gram of which is 20 meters of thread.

Silk stands as one of the oldest known textile materials, boasting a history that spans thousands of years.

Despite their delicate appearance, silk threads exhibit remarkable durability, and the key to this resilience lies in the chemical composition of silk, primarily composed of proteins, notably sericin and fibroin.

Fibroin imparts exceptional strength to silk threads, possessing the ability to absorb significant amounts of water, rendering the threads flexible and resistant to decay. Moreover, silk fibers showcase resistance to UV radiation, ensuring that their strength remains intact even under intense sunlight exposure.

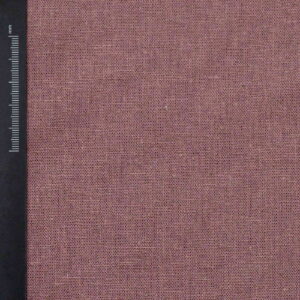

This unique combination of features contributes to the color retention of dyed silk threads, making silk an ideal material not only for clothing production but also for diverse applications such as sewing bedding or home furnishings.

Silk threads, known for their lightweight and gentle feel on the skin, have earned popularity in the fashion industry. The extraordinary durability of silk allows for extended use while maintaining its original and elegant appearance over the years.

Silk embarked on a lengthy journey from China to Europe, and for 2,000 years, the Chinese zealously guarded the secret of its production. China maintained a silk monopoly, exporting this coveted fabric to Europe through the Silk Road. The disclosure of silk production secrets was met with severe consequences, including the possibility of death.

In 550 AD, two monks clandestinely transported this closely guarded knowledge to Byzantium.

Justinian I, the ruler of Byzantium, coveted Chinese silk and the lucrative profits it promised. Legend has it that the monks concealed silkworm eggs within bamboo sticks, cleverly disguised as walking sticks.

However, historical accounts cast doubt on this narrative. Some sources suggest that Byzantium was already engaged in silkworm breeding earlier, proposing the existence of silk production in Syria in the 5th century AD and even as far back as the 4th century BC in Greece.

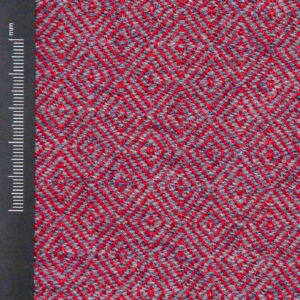

Byzantine silk production flourished rapidly, with mastery of its secrets achieved swiftly. Textiles adorned with intricate patterns emerged, depicting everything from religious scenes to fantastical creatures. The imperial court actively supported this industry by commissioning exclusive designs.

Byzantine silks held great allure in early medieval Europe, garnering appreciation but also a hefty price tag. Consequently, only the wealthiest individuals could indulge in the luxury of owning these coveted fabrics.