Flax plants are typically harvested when they begin beeing brown. The stalks are pulled up from the ground, and the seeds are removed for other uses.

After harvesting, the flax stalks undergo a process called retting, which involves soaking them in water to loosen the fibers from the woody stalk. Retting can take several days to a few weeks, depending on the method and environmental conditions.

After the fibers have been loosened by retting, the stems are broken mechanically to separate the outer shives from the inner fibers. Flax fibers are cleaned in a process called scutching. This involves removing remaining wood debris and impurities from the fibers, leaving clean, long strands of fibers.

The cleaned fibers are then hackled, which involves combing them through fine-toothed metal brushes to separate and align the fibers. This process results in long, smooth linen fibers of consistent quality.

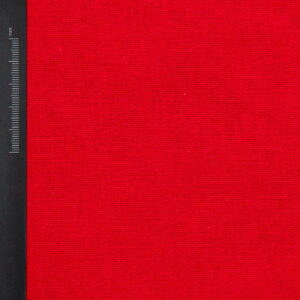

Finally, the prepared flax fibers are spun into linen threads using spinning machines. The threads can vary in thickness depending on the desired end use, ranging from fine threads for delicate fabrics to thicker threads for heavier textiles.

The "30/2" designation in the threads refers to their thickness. What does this mean exactly?

The first number (30 in this case) indicates the thickness of the thread. This number indicates the number of meters per gram of yarn. The higher it is, the thinner the thread is. In this case, it is a thin thread - perfect for sewing, embroidery and even lace-making.

The second number indicates the number of strands twisted together to form a thread. In this case, the "2" means that two individual strands have been twisted together to form the final strand.

So "30/2" means a thin linen thread composed of two single threads, each gram of which is 30 meters of thread.

You can read more on our bloog: How to interpret the thread thickness designation?

The eco-friendliness of linen stems from its sustainable cultivation, biodegradability, low environmental impact in production, durability, versatility, and health benefits. Choosing linen products can contribute to a more sustainable and environmentally friendly lifestyle.

- Flax, the plant from which linen is derived, is a sustainable crop that requires minimal water and pesticides compared to other natural fibers like cotton.

- Linen is also biodegradable, meaning it naturally decomposes at the end of its lifecycle without leaving harmful residues or contributing to environmental pollution.

- Production process of linen typically involves fewer chemicals and energy compared to synthetic fibers like polyester. Additionally, flax plants absorb carbon dioxide from the atmosphere during growth, helping to mitigate greenhouse gas emissions.

- Is known for its durability and longevity. Products made from linen tend to last longer, reducing the need for frequent replacements and ultimately reducing waste.

- Linen is a versatile material that can be used for various purposes, from clothing and household textiles to industrial applications. Its versatility means that fewer resources are needed to produce a wide range of products.

- Is naturally breathable, moisture-wicking, and hypoallergenic, making it a healthy choice for clothing and bedding.

Linen textiles appear to be some of the oldest in the world. Their history goes back many thousands of years. Dyed flax fibers found in a cave in Southeastern Turkey date back to 8,000 BC.

In Egypt, flax was grown as early as 5,000 BC, and linen garments were used by the pharaohs.

Linen textiles and threads was also used by the ancient Greeks and Romans. In the Middle Ages, linen was one of the most common fabric for clothing in Europe. It was used for both everyday wear and for special occasions. In the 19th century, cotton became the more popular fabric for clothing, but linen remained popular for formal wear. Today, linen is still used for clothing, bedding, and table linens.